1

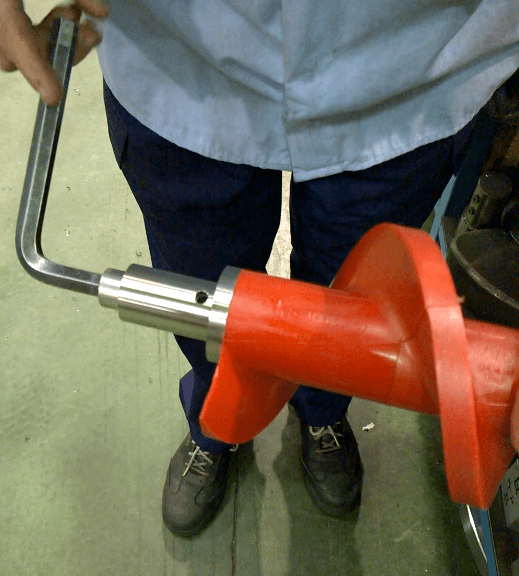

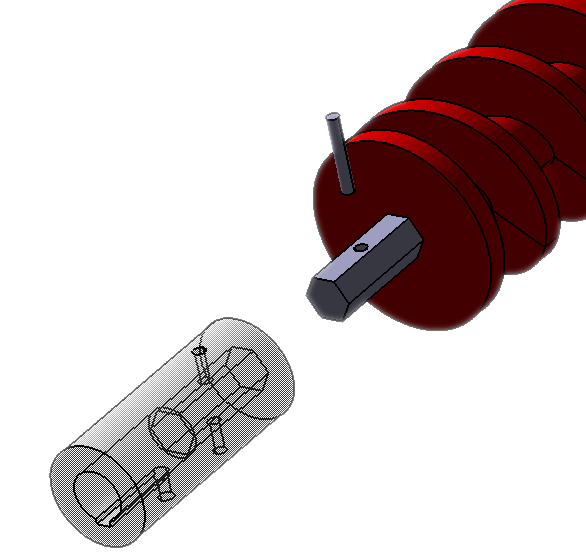

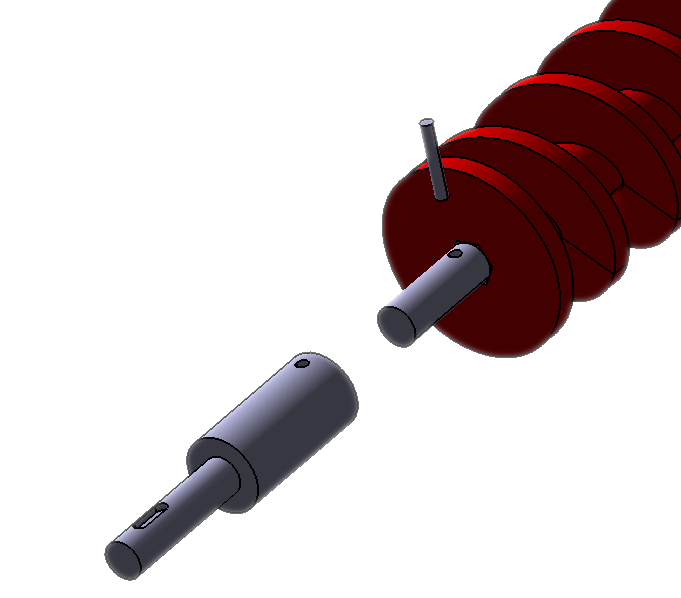

Prepare your axles

Once you have received your modules, prepare axles you need for your Archimedys™ screw assembly. Attach an end and drive shaft to the end of the axle. Always provide a threaded hole at the end of the axle to allow modules locking.

The drive shaft diameter must always be at least equal to the module core diameter.

2

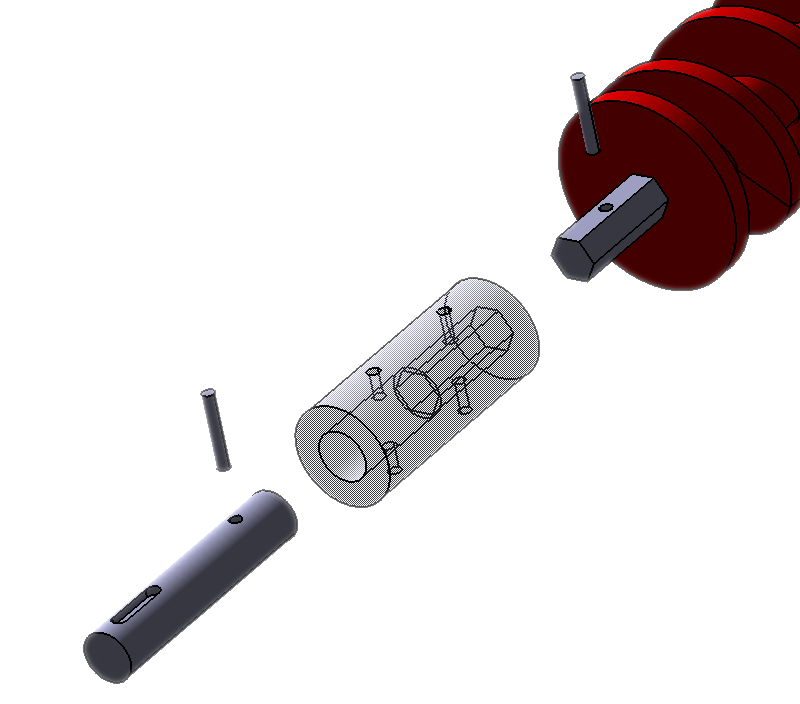

Assemble your modules

Simply stack modules on the shaft according to the screw profile you have defined. The supporting faces of beginning or end modules must be flat. TRH and FRH have a flat contact face as standard. It’s possible to machinize in order to adjust the screw lenght.

Reminder : The drive shaft diameter must always be at least equal to the module core diameter

3

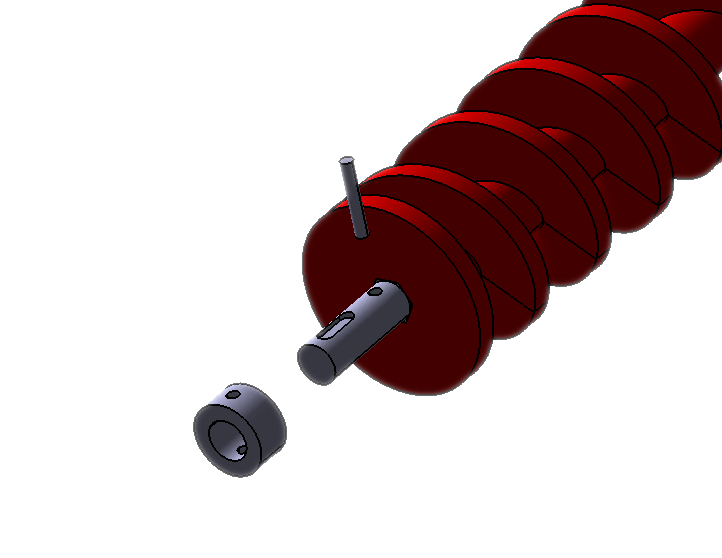

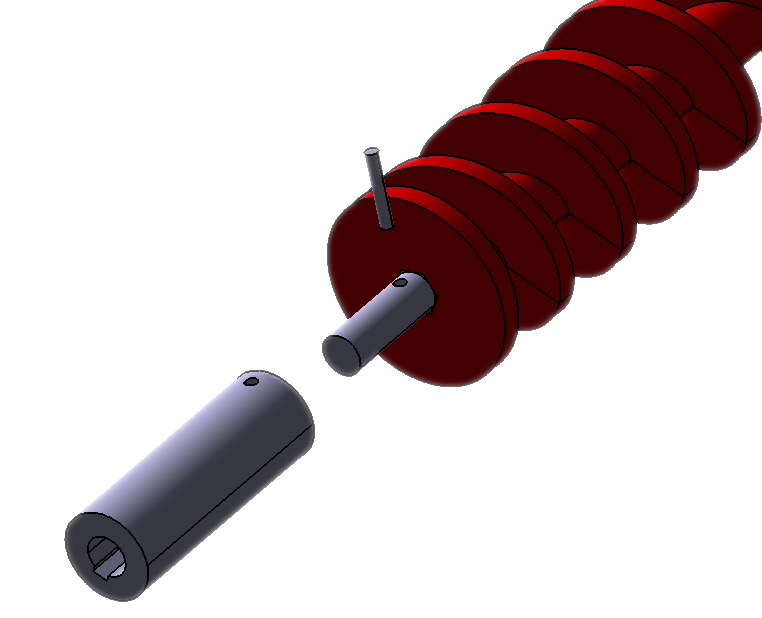

Lock your screw

Once your screw is assembled, insert the end shaft and lock with a clamping screw.

Different end side configurations are possible:

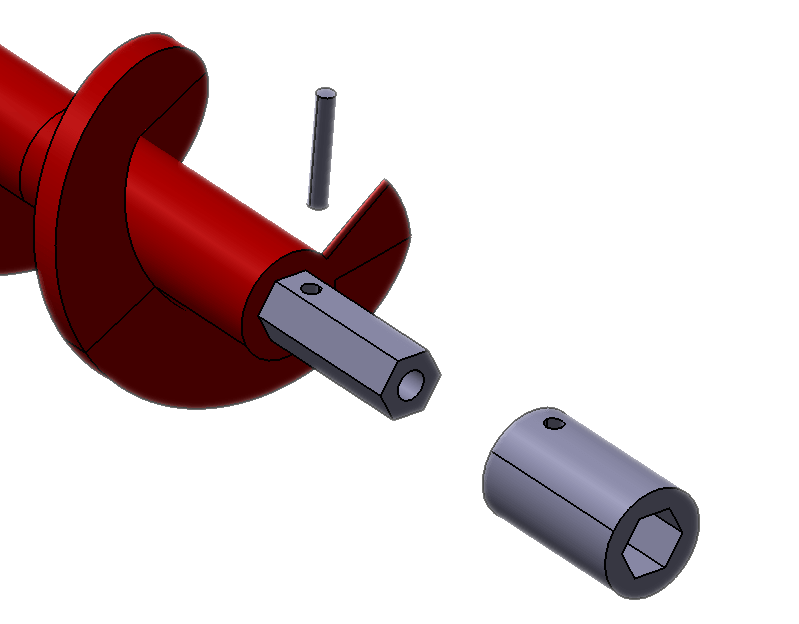

A

Without machining the axle and using a standard hexagon socket.

Shafts locking is done with a simply drilled pin when all modules are in position. This side can be used to mount bearings.

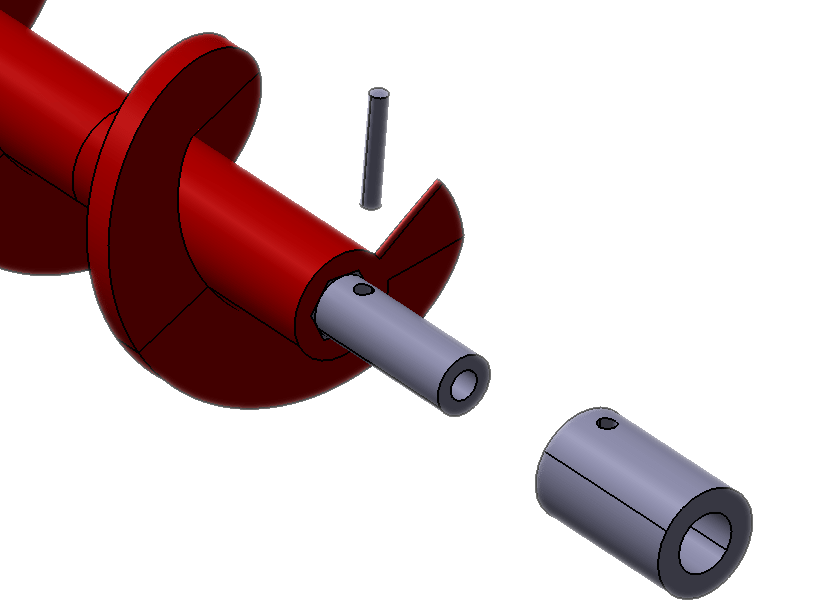

B

The hexagonal shaft is turned to reach an appropriate diameter. A simple bush is then used to lock modules in position using a pin.

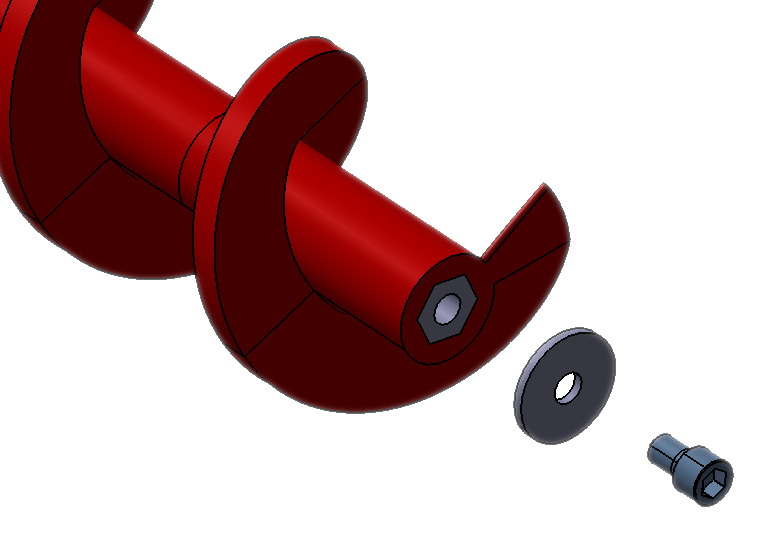

C

When the material flows in the screw direction, it’s possible to lock modules in position with a conventional screw and a steel washer.

Different drive side configurations are also possible:

1

Configuration 1: the hexagonal shaft is not machinized. You can use a standard hexagon bush with a cylindrical area to adapt the motor connection. The bushes are fixed with two pins. The keyway can be made directly on bushes.

2

Configuration 2: The hexagonal shaft is not machinized. You can add an extra axle on the bushings when hollow couplings are used.

3

Configuration 3: In this configuration, you have to machinize the shaft and add bushings. The fixing is done with two pins on the shaft side.

4

Configuration 4: You can machinize the end shaft and add a steel bushing to lock modules in position. The keyway is made on the axle.

5

Configuration 5: The hexagonal shaft is machinized according to the end shaft shape. This configuration is mainly used when a long drive shaft is required.